What is a Forward Curved Impeller?

A forward curved impeller is characterised by a relatively large number of shallow blades facing the direction of rotation.

For this type of impeller, flow from the impeller is produced in a tangential direction. The forward curve of the blade imparts kinetic energy to the air requiring a scroll housing to convert the kinetic energy into static pressure. For any given constant speed, the input power characteristic increases as flow increases from zero to maximum. At higher flow rates, care must therefore be taken that the load presented by the impeller does not exceed the rating of the driving motor.

Key Features and Benefits

- Lower speed of operation than backward curved fans

- Compact impeller design

- Cost-effective pressed steel or aluminium construction

- Can be used for high temperature applications

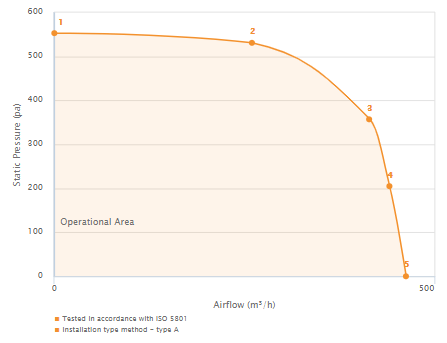

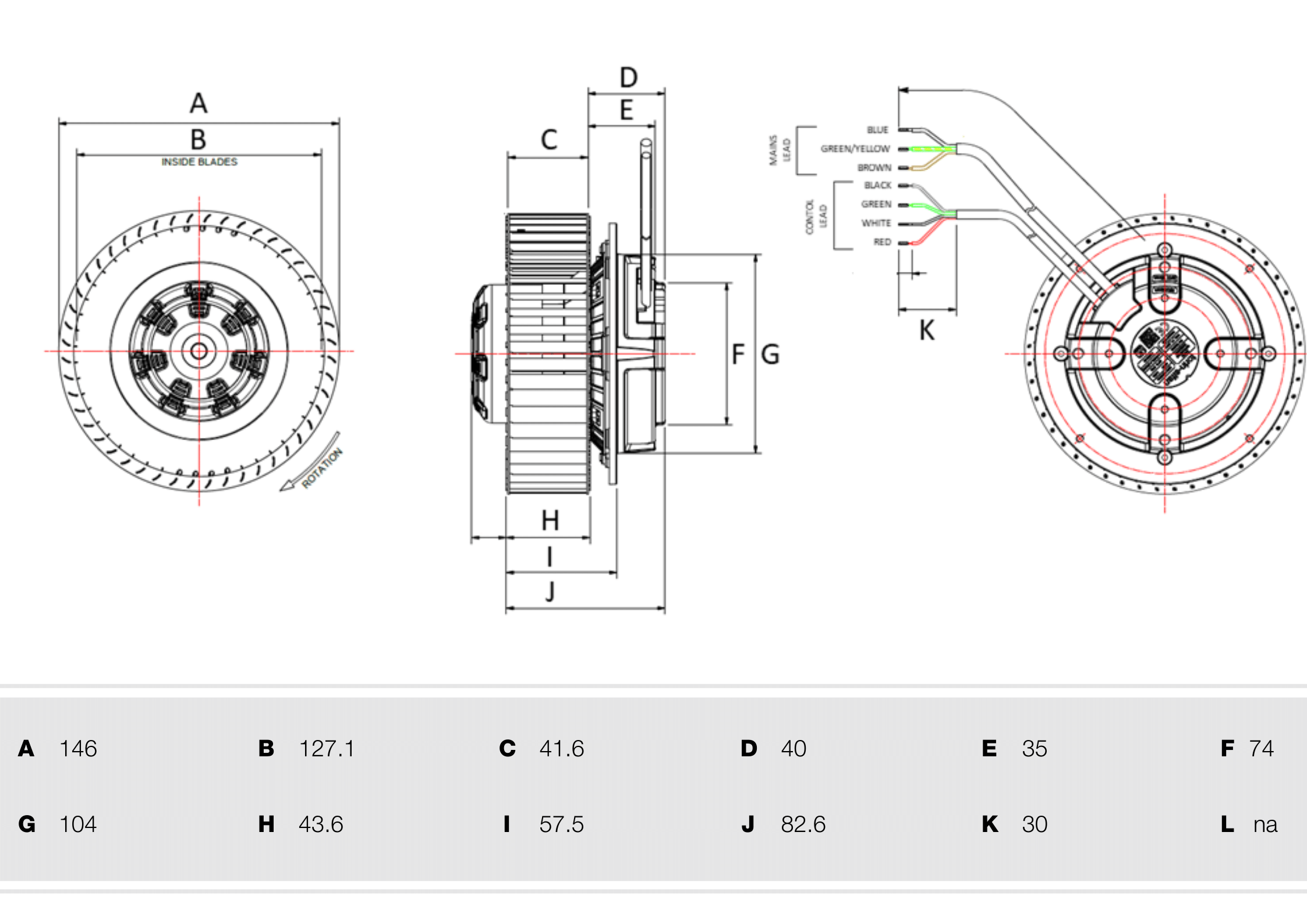

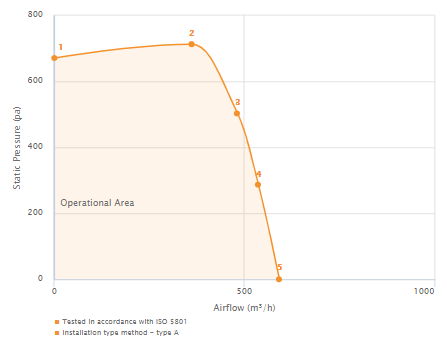

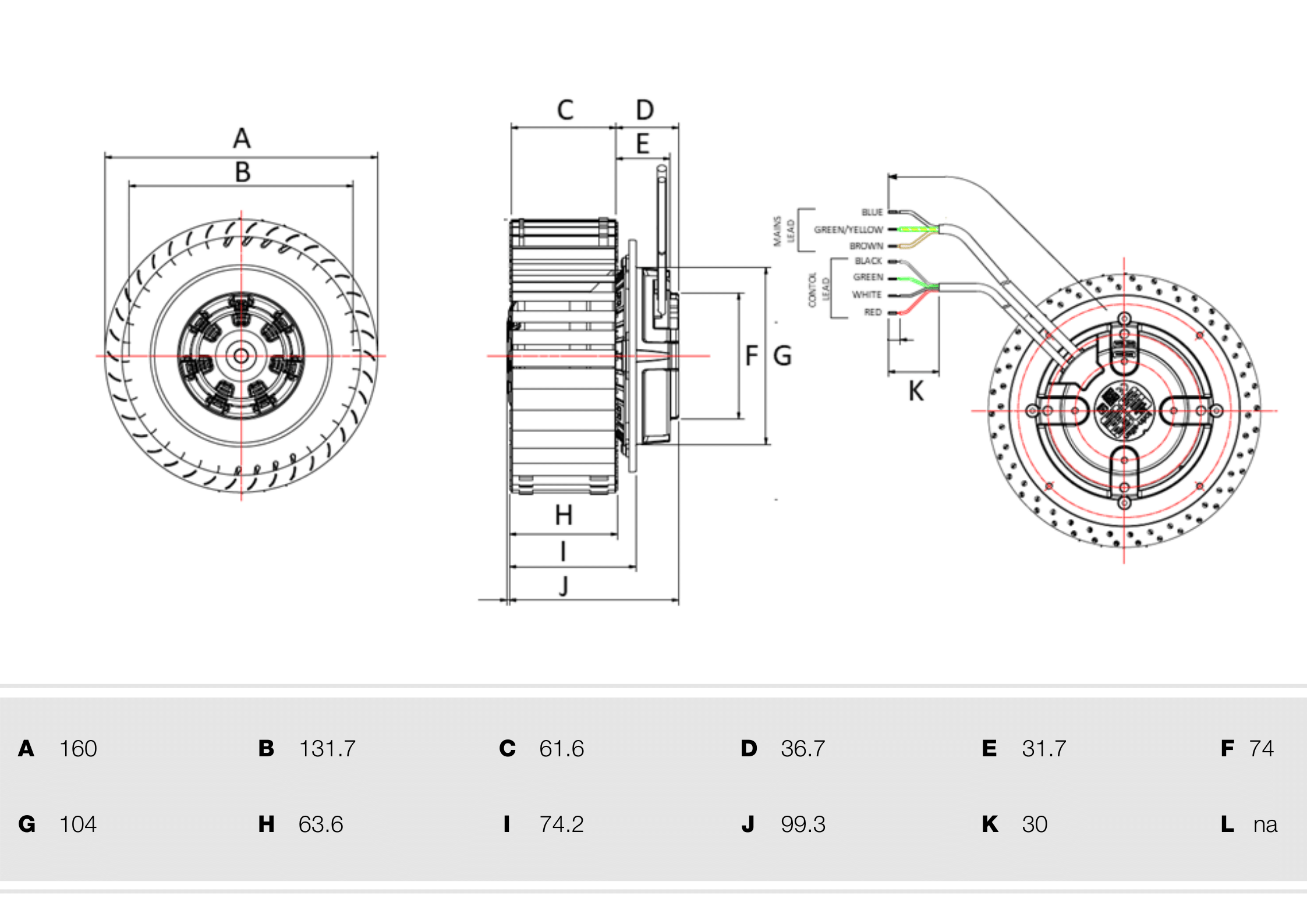

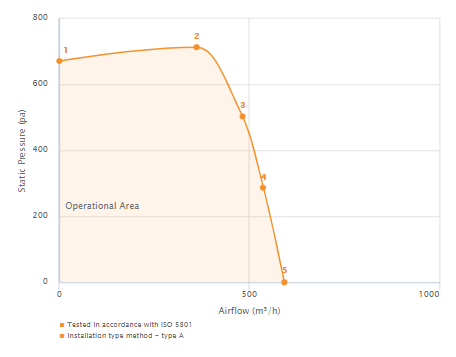

| Supply (V/Ph/Hz) | 230 / 1 / 50/60 |

|---|---|

| Max Airflow (m³/h) | 463 |

| Max Current (A) | 1.63 |

| Max Input Power (W) | 186 |

| Max Speed (rpm) | 3000 |

| ErP Efficiency Rating (FMEG) | 53 |

| Ip Rating | 54 |

| Motor Insulation Class | B |

| Temperature Range (°C) | -20 to +60 |

| Weight (KG) | 1.38 |

What is a Forward Curved Impeller?

A forward curved impeller is characterised by a relatively large number of shallow blades facing the direction of rotation.

For this type of impeller, flow from the impeller is produced in a tangential direction. The forward curve of the blade imparts kinetic energy to the air requiring a scroll housing to convert the kinetic energy into static pressure. For any given constant speed, the input power characteristic increases as flow increases from zero to maximum. At higher flow rates, care must therefore be taken that the load presented by the impeller does not exceed the rating of the driving motor.

Key Features and Benefits

- Lower speed of operation than backward curved fans

- Compact impeller design

- Cost-effective pressed steel or aluminium construction

- Can be used for high temperature applications

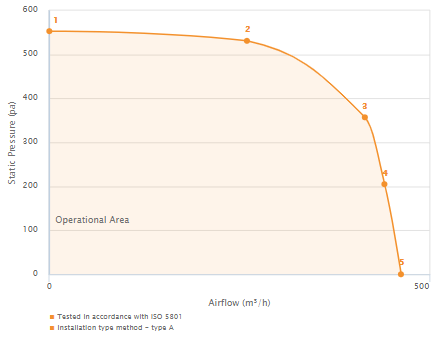

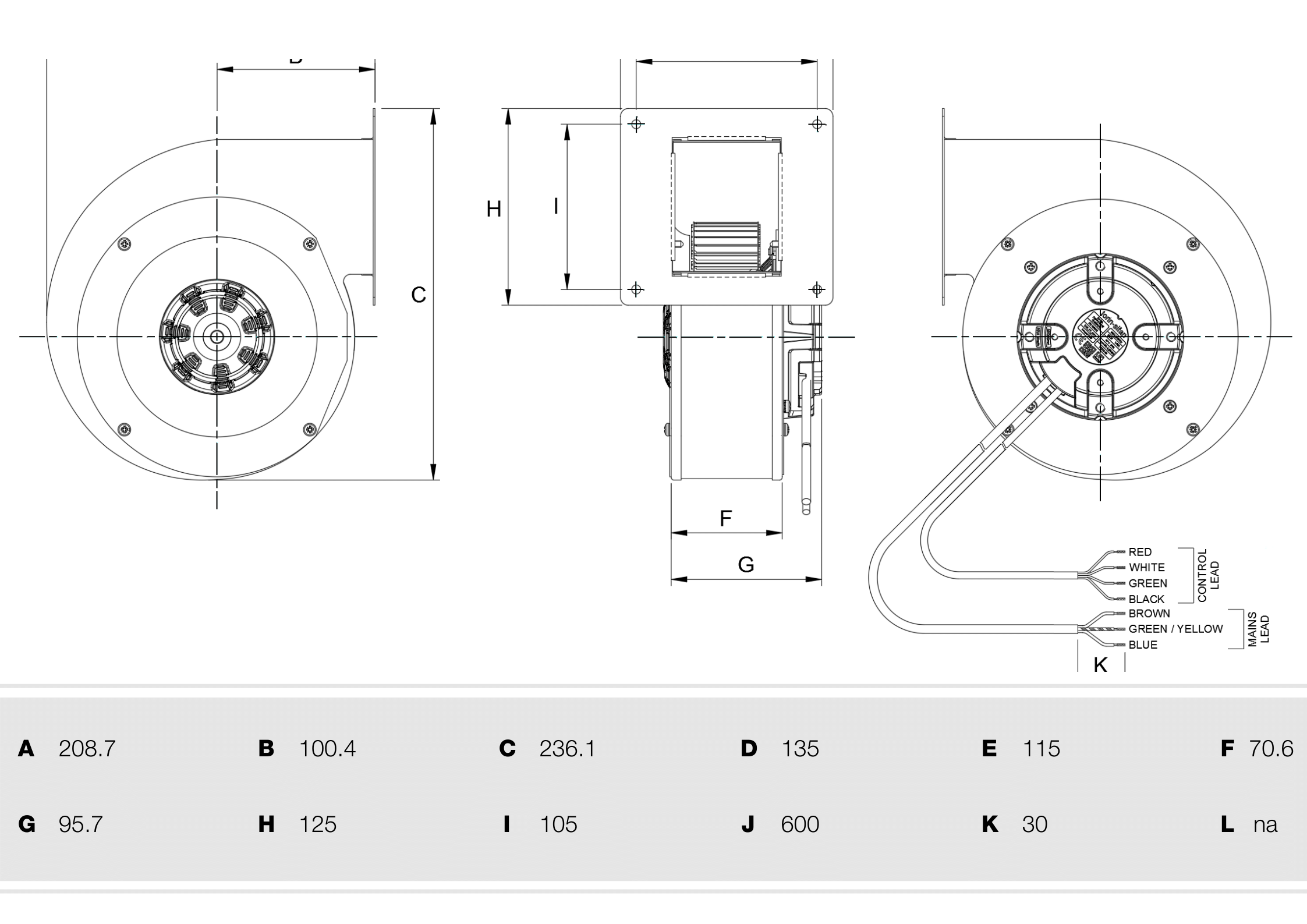

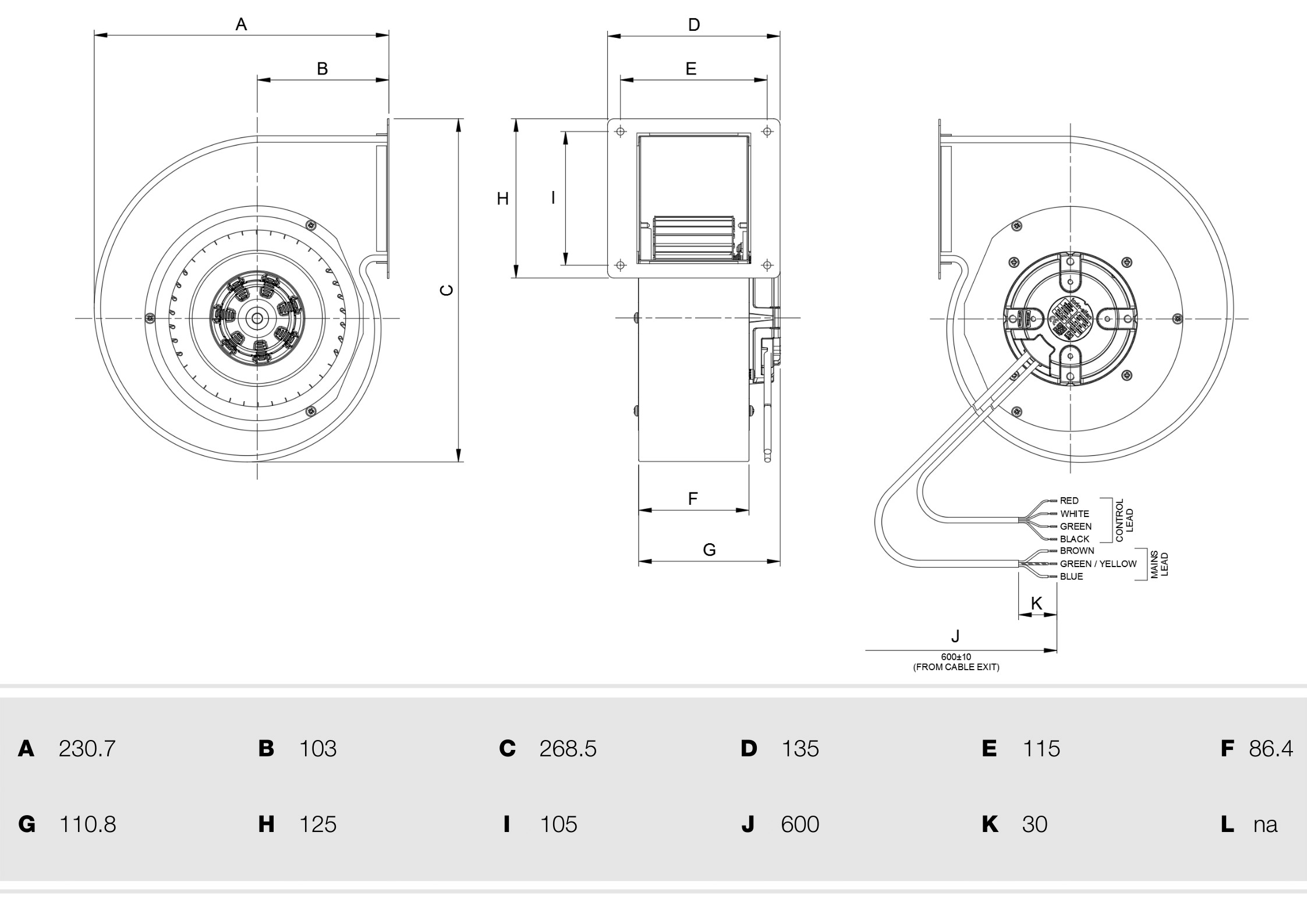

| Supply (V/Ph/Hz) | 230 / 1 / 50/60 |

|---|---|

| Max Airflow (m³/h) | 592 |

| Max Current (A) | 1.62 |

| Max Input Power (W) | 183 |

| Max Speed (rpm) | 3000 |

| ErP Efficiency Rating (FMEG) | 60 |

| Ip Rating | 54 |

| Motor Insulation Class | B |

| Temperature Range (°C) | -25 to +60 |

| Weight (KG) | 1.49 |

What is a Forward Curved Impeller?

A forward curved impeller is characterised by a relatively large number of shallow blades facing the direction of rotation.

For this type of impeller, flow from the impeller is produced in a tangential direction. The forward curve of the blade imparts kinetic energy to the air requiring a scroll housing to convert the kinetic energy into static pressure. For any given constant speed, the input power characteristic increases as flow increases from zero to maximum. At higher flow rates, care must therefore be taken that the load presented by the impeller does not exceed the rating of the driving motor.

Key Features and Benefits

- Lower speed of operation than backward curved fans

- Compact impeller design

- Cost-effective pressed steel or aluminium construction

- Can be used for high temperature applications

| Supply (V/Ph/Hz) | 198 / 1 / 50/60 |

|---|---|

| Max Airflow (m³/h) | 463 |

| Max Current (A) | 1.63 |

| Max Input Power (W) | 186 |

| Max Speed (rpm) | 3000 |

| ErP Efficiency Rating (FMEG) | 53 |

| Ip Rating | 54 |

| Motor Insulation Class | B |

| Temperature Range (°C) | -20 to +60 |

| Weight (KG) | 2.40 |

What is a Forward Curved Impeller?

A forward curved impeller is characterised by a relatively large number of shallow blades facing the direction of rotation.

For this type of impeller, flow from the impeller is produced in a tangential direction. The forward curve of the blade imparts kinetic energy to the air requiring a scroll housing to convert the kinetic energy into static pressure. For any given constant speed, the input power characteristic increases as flow increases from zero to maximum. At higher flow rates, care must therefore be taken that the load presented by the impeller does not exceed the rating of the driving motor.

Key Features and Benefits

- Lower speed of operation than backward curved fans

- Compact impeller design

- Cost-effective pressed steel or aluminium construction

- Can be used for high temperature applications

| Supply (V/Ph/Hz) | 198 / 1 / 50/60 |

|---|---|

| Max Airflow (m³/h) | 592 |

| Max Current (A) | 1.62 |

| Max Input Power (W) | 183 |

| Max Speed (rpm) | 3000 |

| ErP Efficiency Rating (FMEG) | 60 |

| Ip Rating | 54 |

| Motor Insulation Class | B |

| Temperature Range (°C) | -20 to +60 |

| Weight (KG) | 2.60 |

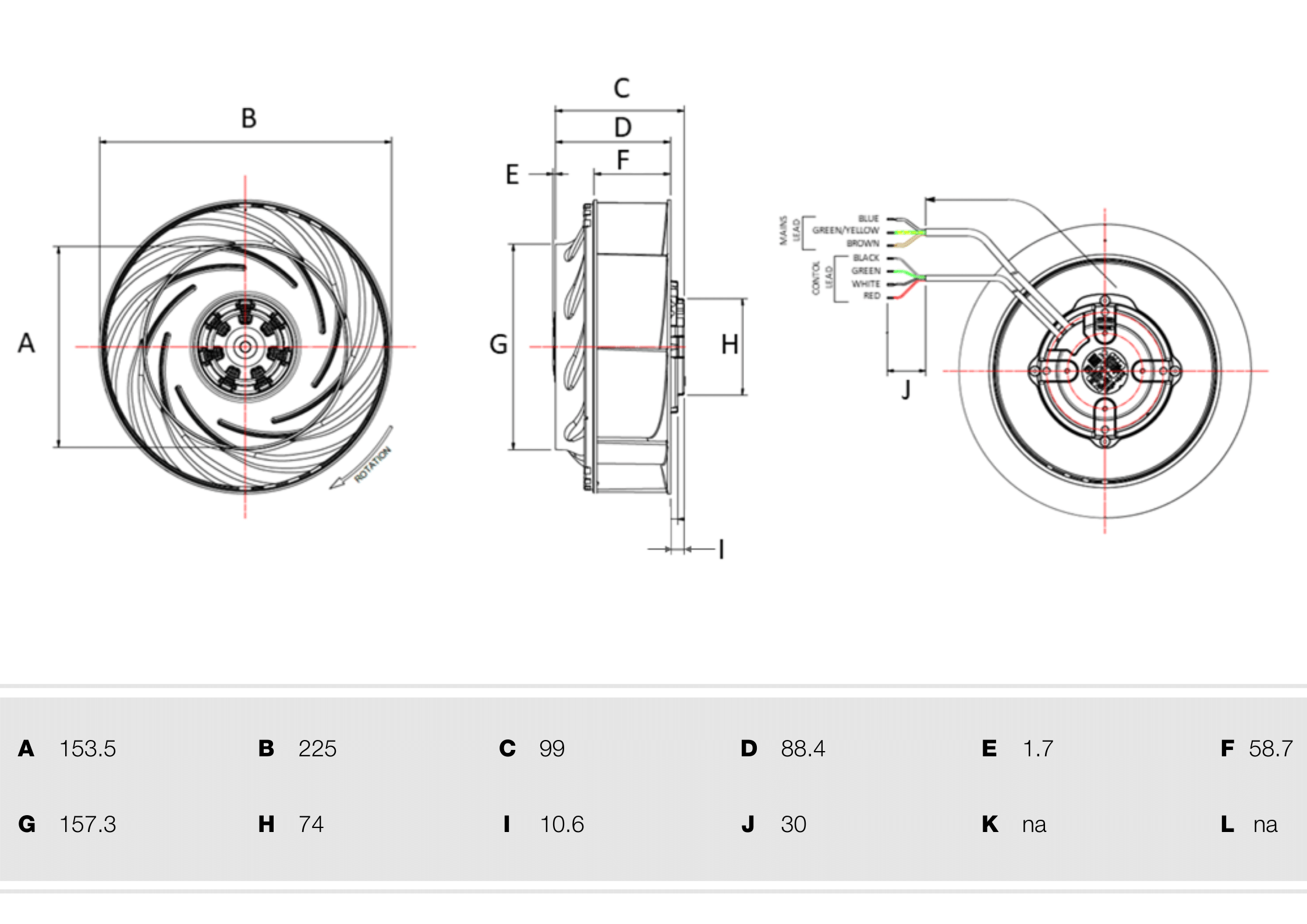

What is a Backward Curved Impeller?

They are called Backward Curved due to the direction of rotation. The blades curve backwards from the inner edge to the outer edge, relative to the direction of rotation, and may be of plate or aerofoil form.

For this type of impeller, flow is produced in a radial direction because the impeller develops static pressure across the longer length of blade. On the front side of the blade a positive pressure is generated pushing the air outwards and on the reverse side of the blade a negative pressure is generated. This negative pressure draws air in to the space so that the front side of the following blade picks this air up and pushes it outwards.

Key Features and Benefits

- Higher efficiency than forward curved products

- Can be utilised without additional scroll housing

- Peak power demand is a centre of performance characteristic, reducing potential for motor overloading at lower pressures

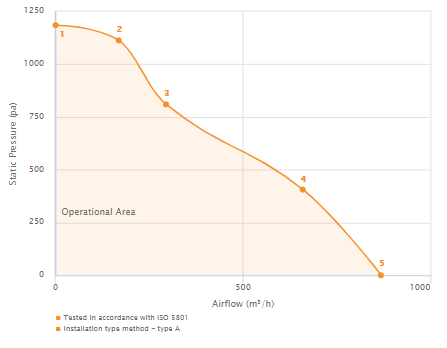

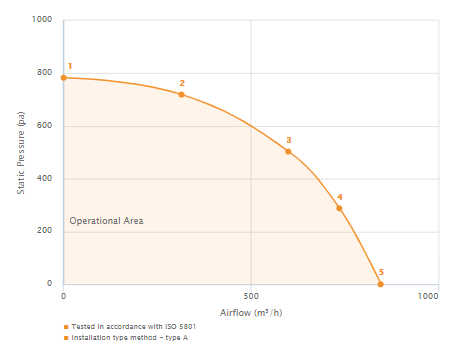

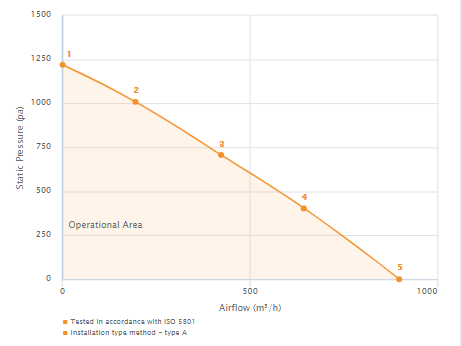

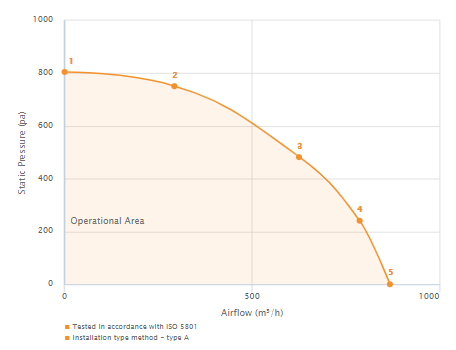

| Supply (V/Ph/Hz) | 198 / 1 / 50/60 |

|---|---|

| Max Airflow (m³/h) | 869 |

| Max Current (A) | 1.62 |

| Max Input Power (W) | 185 |

| Max Speed (rpm) | 4900 |

| ErP Efficiency Rating (FMEG) | 71 |

| Ip Rating | 54 |

| Motor Insulation Class | B |

| Temperature Range (°C) | -25 to +60 |

| Weight (KG) | 1.46 |

What is a Backward Curved Impeller?

They are called Backward Curved due to the direction of rotation. The blades curve backwards from the inner edge to the outer edge, relative to the direction of rotation, and may be of plate or aerofoil form.

For this type of impeller, flow is produced in a radial direction because the impeller develops static pressure across the longer length of blade. On the front side of the blade a positive pressure is generated pushing the air outwards and on the reverse side of the blade a negative pressure is generated. This negative pressure draws air in to the space so that the front side of the following blade picks this air up and pushes it outwards.

Key Features and Benefits

- Higher efficiency than forward curved products

- Can be utilised without additional scroll housing

- Peak power demand is a centre of performance characteristic, reducing potential for motor overloading at lower pressures

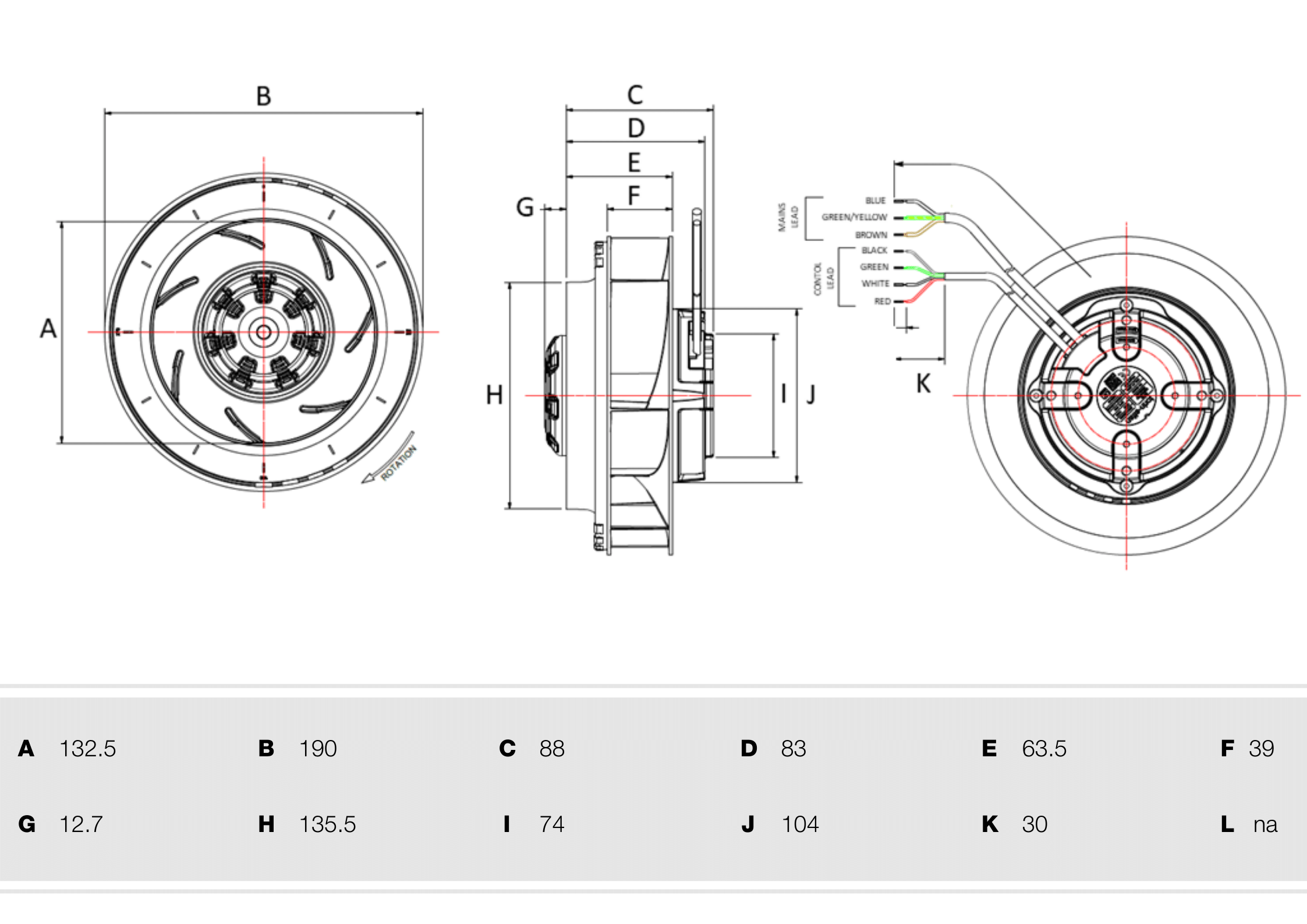

| Supply (V/Ph/Hz) | 198 / 1 / 50/60 |

|---|---|

| Max Airflow (m³/h) | 847 |

| Max Current (A) | 1.57 |

| Max Input Power (W) | 176 |

| Max Speed (rpm) | 3300 |

| ErP Efficiency Rating (FMEG) | 77 |

| Ip Rating | 54 |

| Motor Insulation Class | B |

| Temperature Range (°C) | -20 to +60 |

| Weight (KG) | 1.72 |

What is a Backward Curved Impeller?

They are called Backward Curved due to the direction of rotation. The blades curve backwards from the inner edge to the outer edge, relative to the direction of rotation, and may be of plate or aerofoil form.

For this type of impeller, flow is produced in a radial direction because the impeller develops static pressure across the longer length of blade. On the front side of the blade a positive pressure is generated pushing the air outwards and on the reverse side of the blade a negative pressure is generated. This negative pressure draws air in to the space so that the front side of the following blade picks this air up and pushes it outwards.

Key Features and Benefits

- Higher efficiency than forward curved products

- Can be utilised without additional scroll housing

- Peak power demand is a centre of performance characteristic, reducing potential for motor overloading at lower pressures

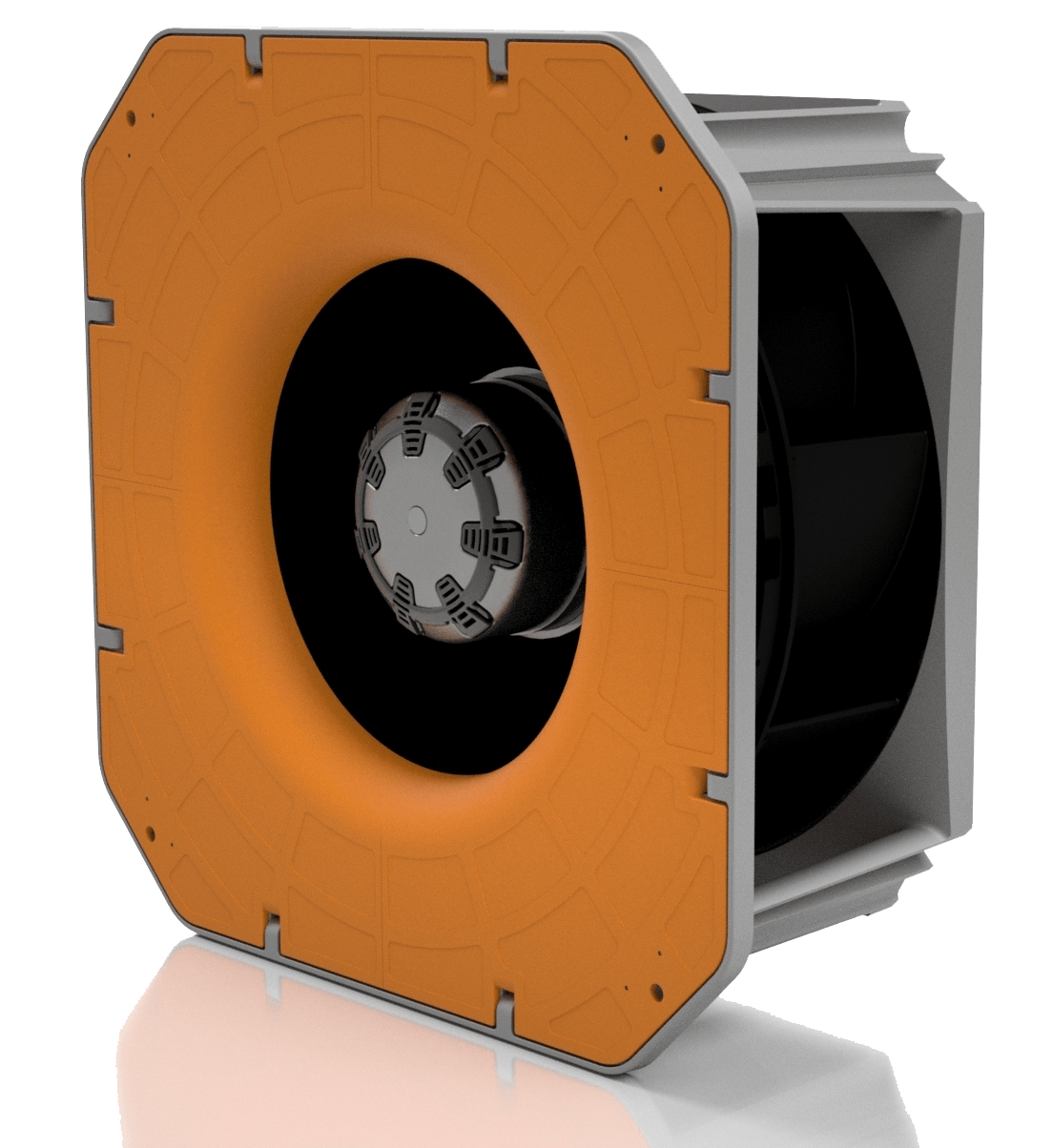

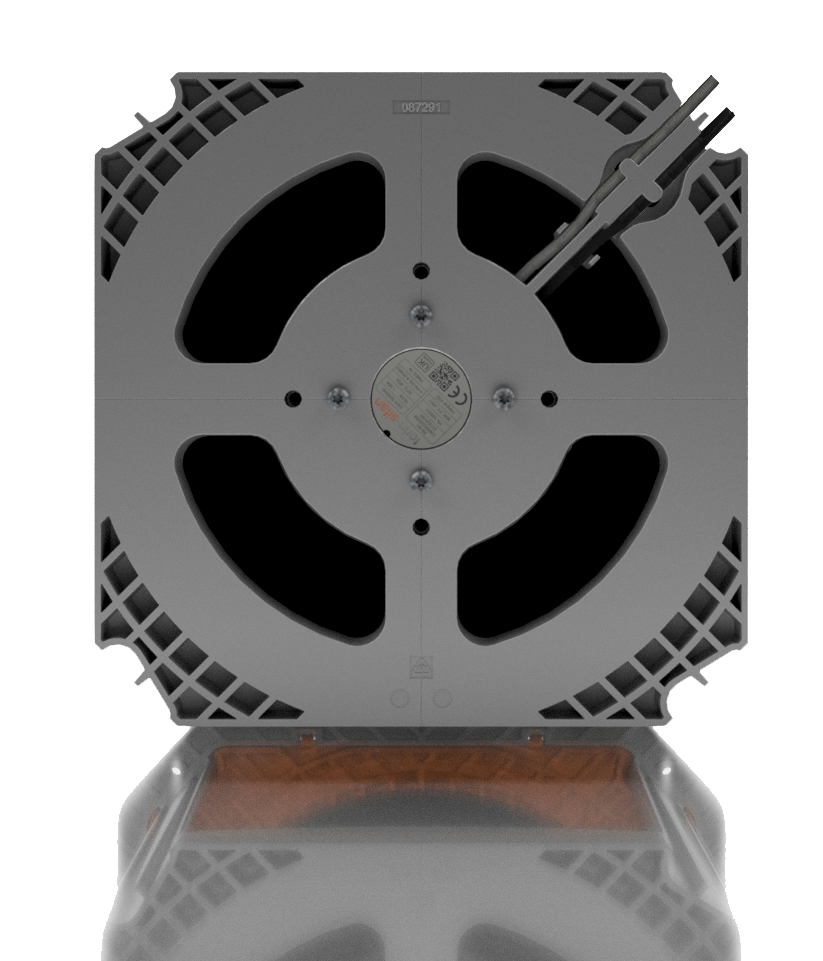

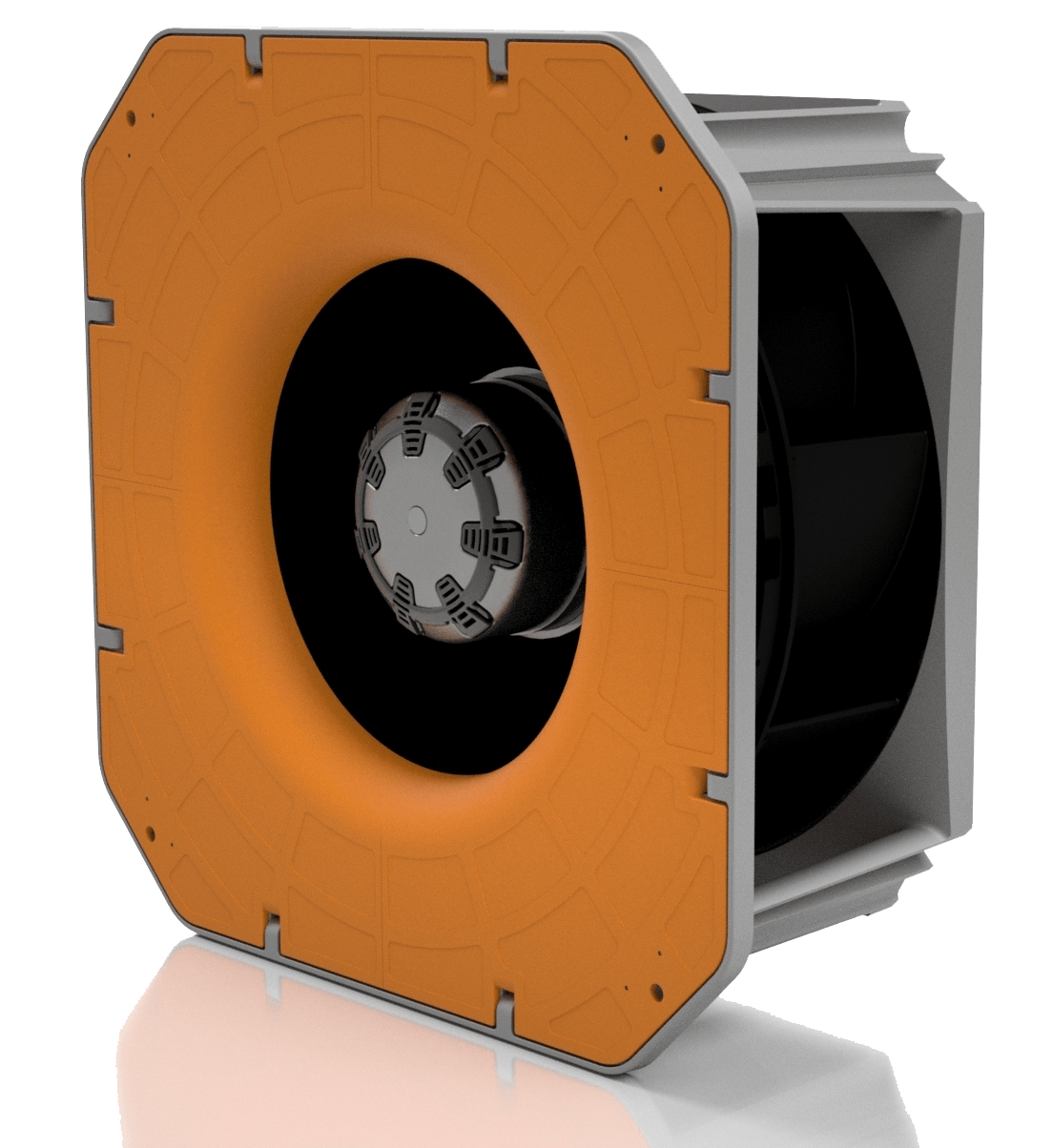

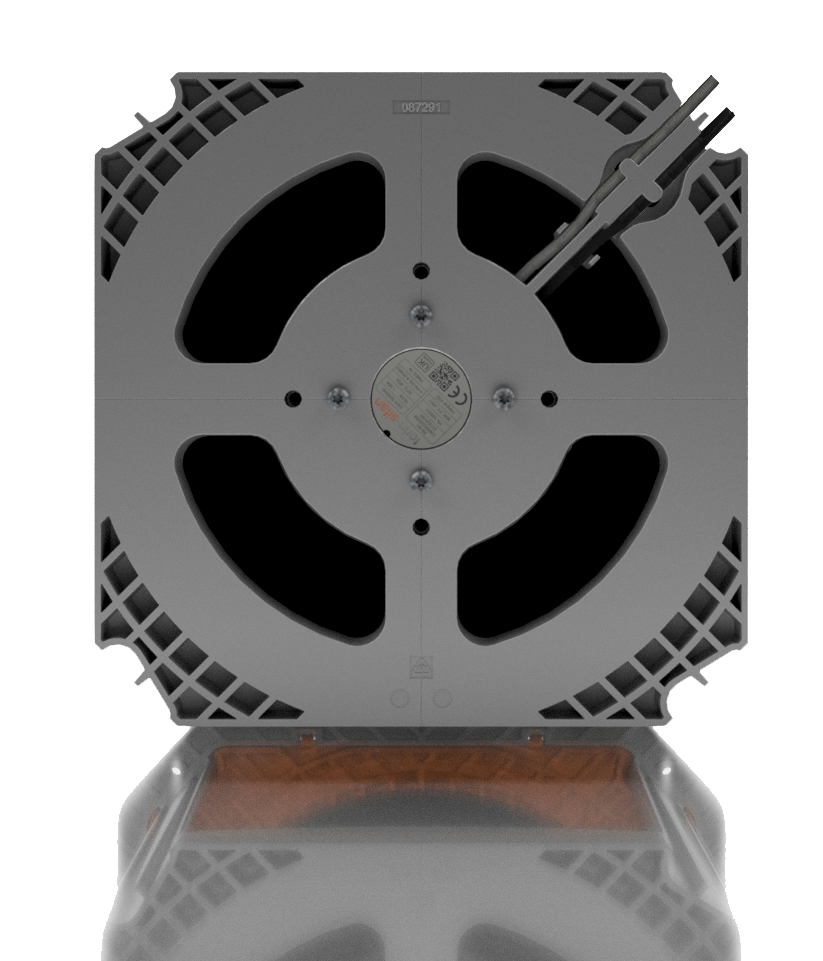

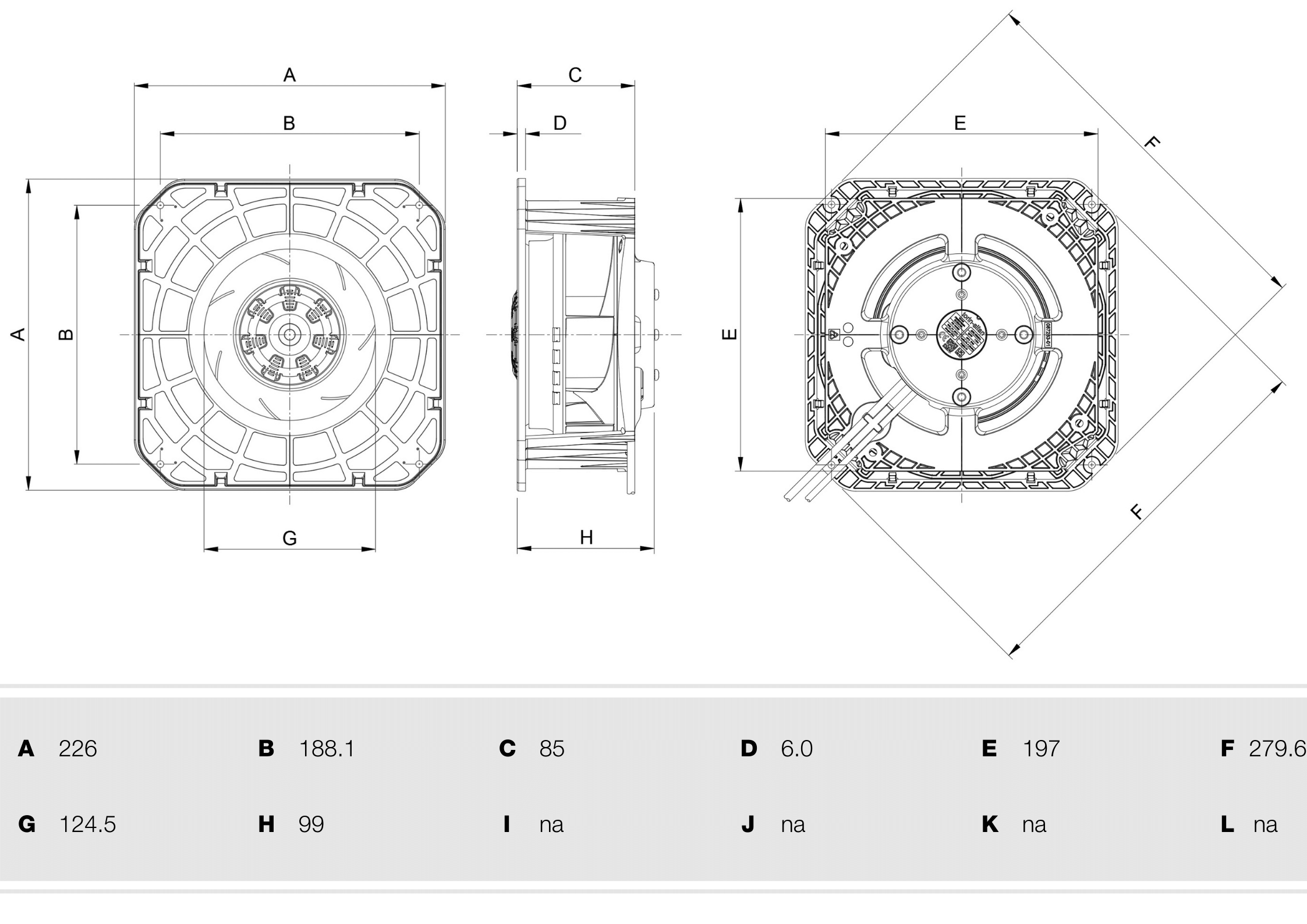

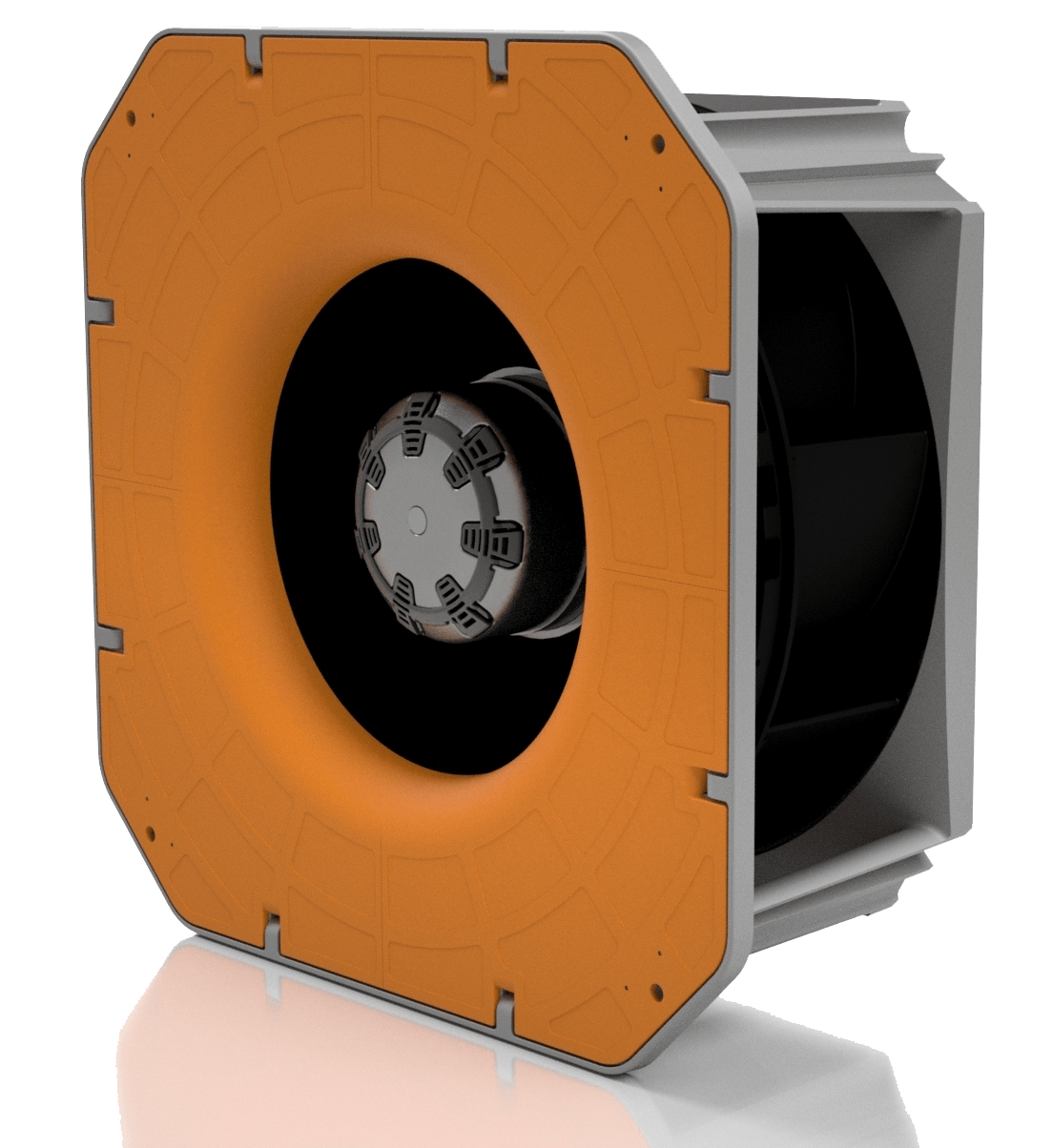

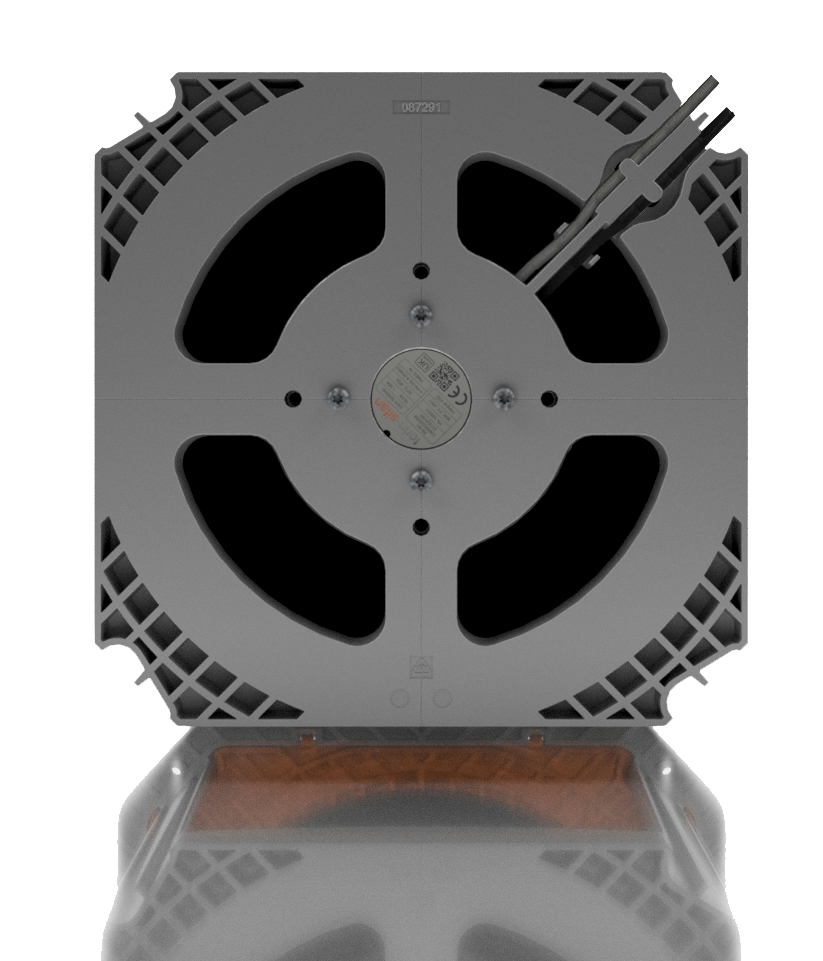

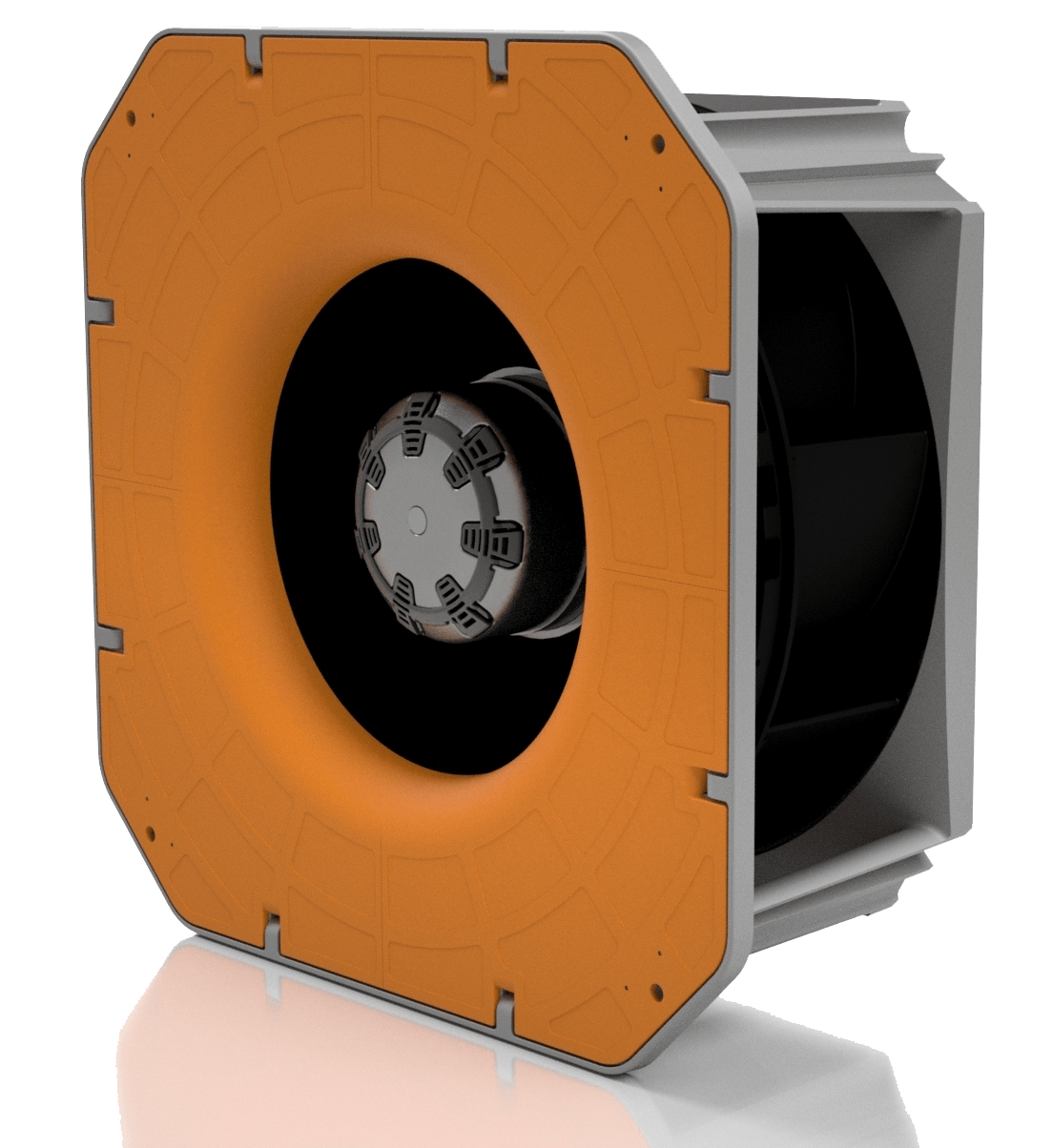

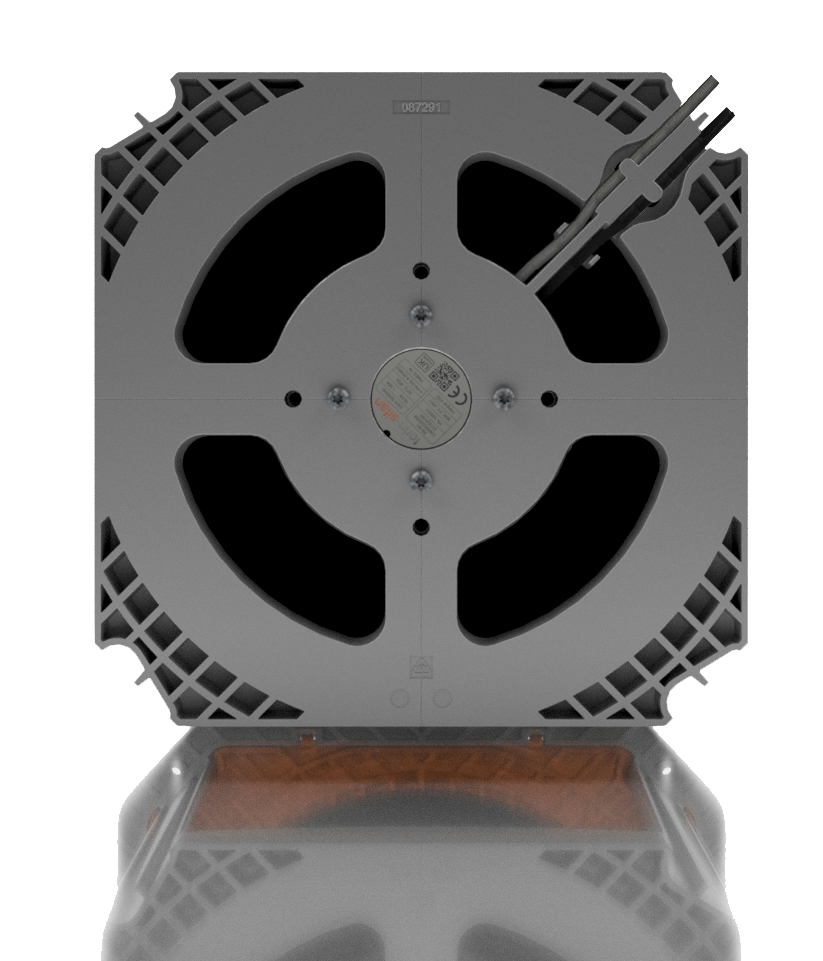

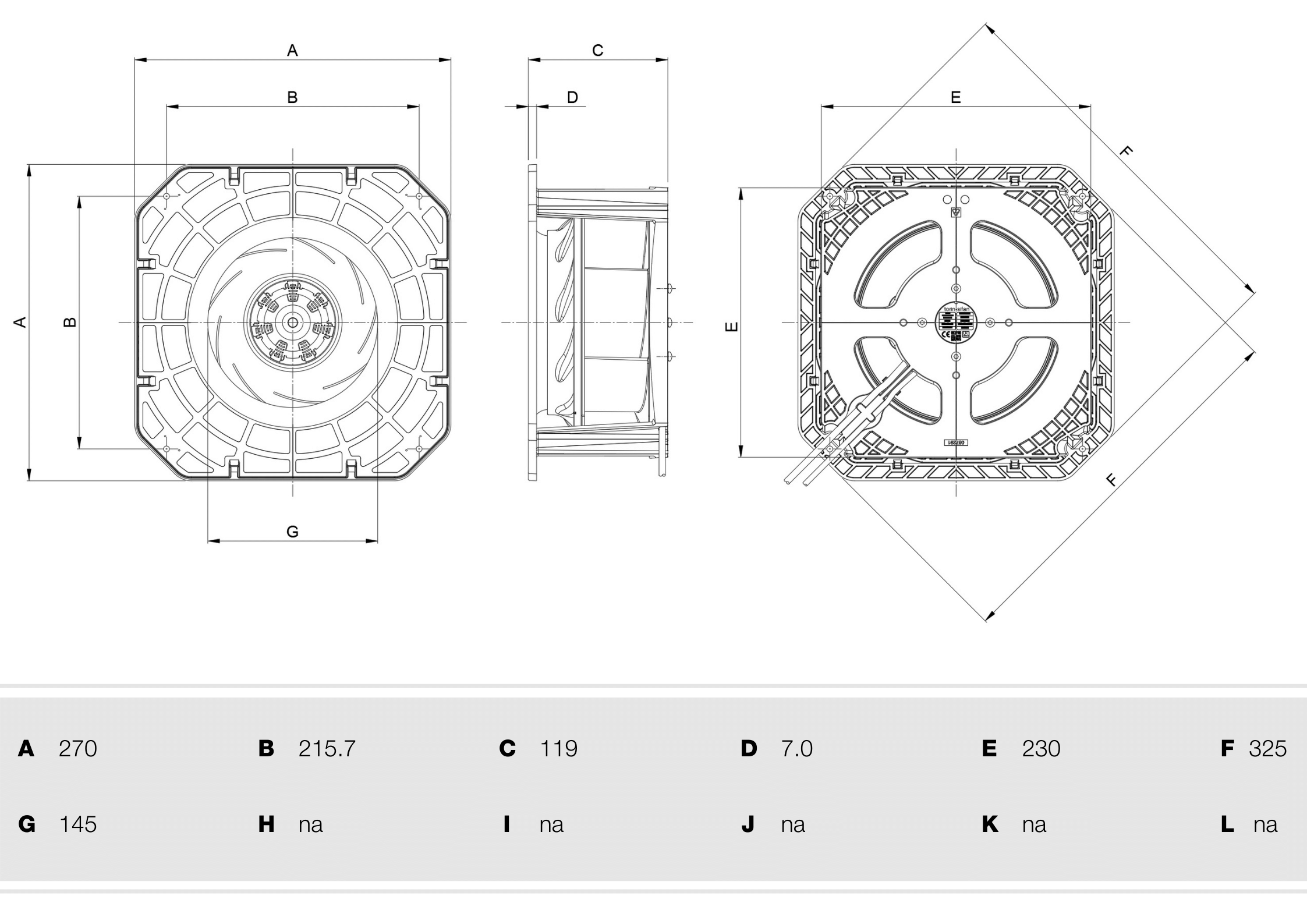

Why choose a Cassette Frame?

Cassette frames essentially make it easier for you to install our product, by simply adding it to the application you desire. We have set the optimal inlet condition so our motorised impellers run efficiently and quietly to meet your expectations. A minor offset from the optimal inlet positioning will effect performance, therefore our cassettes are the best option to guarantee results. We are happy to discuss in more detail if required.

| Supply (V/Ph/Hz) | 198 / 1 / 50/60 |

|---|---|

| Max Airflow (m³/h) | 899 |

| Max Current (A) | 1.57 |

| Max Input Power (W) | 181 |

| Max Speed (rpm) | 4900 |

| ErP Efficiency Rating (FMEG) | 70 |

| Ip Rating | 54 |

| Motor Insulation Class | B |

| Temperature Range (°C) | -20 to +60 |

| Weight (KG) | 1.91 |

What is a Backward Curved Impeller?

They are called Backward Curved due to the direction of rotation. The blades curve backwards from the inner edge to the outer edge, relative to the direction of rotation, and may be of plate or aerofoil form.

For this type of impeller, flow is produced in a radial direction because the impeller develops static pressure across the longer length of blade. On the front side of the blade a positive pressure is generated pushing the air outwards and on the reverse side of the blade a negative pressure is generated. This negative pressure draws air in to the space so that the front side of the following blade picks this air up and pushes it outwards.

Key Features and Benefits

- Higher efficiency than forward curved products

- Can be utilised without additional scroll housing

- Peak power demand is a centre of performance characteristic, reducing potential for motor overloading at lower pressures

Why choose a Cassette Frame?

Cassette frames essentially make it easier for you to install our product, by simply adding it to the application you desire. We have set the optimal inlet condition so our motorised impellers run efficiently and quietly to meet your expectations. A minor offset from the optimal inlet positioning will effect performance, therefore our cassettes are the best option to guarantee results. We are happy to discuss in more detail if required.

| Supply (V/Ph/Hz) | 198 / 1 / 50/60 |

|---|---|

| Max Airflow (m³/h) | 868 |

| Max Current (A) | 1.56 |

| Max Input Power (W) | 181 |

| Max Speed (rpm) | 3300 |

| ErP Efficiency Rating (FMEG) | 74 |

| Ip Rating | 54 |

| Motor Insulation Class | B |

| Temperature Range (°C) | -20 to +60 |

| Weight (KG) | 2.47 |

EC Forward and Backward Curved 170W

Our EC motorised impellers utilise the latest three-core technology, ensuring best in class efficiency levels as well as whisper quiet operation. This range of EC centrifugal motorised impellers and fans is optimised to provide aerodynamic efficiency and low acoustic noise at the higher static pressures encountered in today’s ventilation applications.