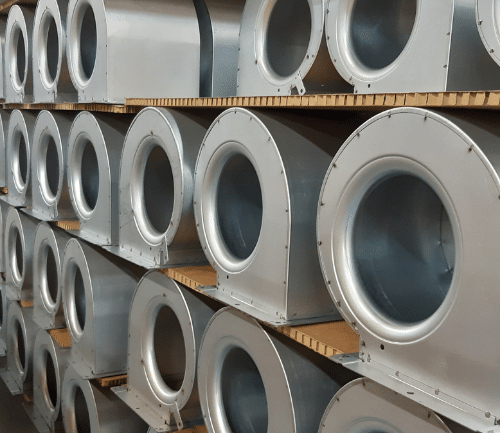

Sometimes known as blowers, centrifugal fans are generally found in commercial and industrial HVAC (heating, ventilation and air conditioning) markets. They can be used for a variety of applications such as commercial ventilation, domestic boilers and heat recovery systems. There are a wide range of centrifugal fans available based on the different airflows required for certain applications. But what are the different types of centrifugal fans? Here we have picked out four of the main types of centrifugal fan to help answer this question.

Forward curved centrifugal fans

Forward curved centrifugal fans have a relatively large amount of forward facing curved impeller blades (facing the direction of rotation of the impeller). The blades are relatively shallow in terms of the length of the blade arc. Forward curved fans can either be of a single-inlet or double-inlet type with air inlet to the impellers at right angles to the direction of airflow through the fan.

This type of fan requires a fan scroll housing or volute to convert the high velocity air exiting the blades into static pressure and also to provide directionality for the output airflow. The power demand for this type of fan steadily increases in proportion to the airflow being delivered, meaning that motors can easily be overloaded if operating at higher flow rates and lower pressures.

This type of fan is particularly suited to higher flow rate applications requiring lower operating speeds in comparison with a backward curved fan, but has a lower overall efficiency when compared with a backward curved fan.

Backward curved centrifugal fans

Backward curved centrifugal fans typically have fewer impeller blades which are facing away from the direction of rotation of the impeller. The blades have a longer blade arc length in comparison with forward curved fans, so in general tend to be larger in diameter.

The impellers usually have a shaped inlet shroud at the inlet side to the impeller and can be either single-inlet or double-inlet in design. In contrast to a forward curved impeller, static pressure is developed across the depth of the impeller blade meaning that backward curved impellers can be configured for use either with or without a fan scroll. Adding a fan scroll can provide a better pressure characteristic so is therefore suited to combustion (boiler) fan applications or applications which need a higher pressure capability. Operation without a fan scroll is more suited to applications with higher flow rate requirements. The power demand for a backward curved impeller fan, typically peaks around the middle of its performance characteristic, so that the motor is less liable to be overloaded at lower pressures & higher flow rates.

Backward curved fans offer an improved level of efficiency in comparison to a forward curved impeller type, but typically require higher speeds of operation to achieve higher airflow rates.

Crossflow / tangential fans

Crossflow / tangential fans consist of an extended forward curved impeller type (similar to a cylindrical lawn mower blade) and also requires the use of a type of fan scroll (volute). Instead of the air entering the impeller through the eye of the impeller, for this type of fan the scroll housing has an opening on one side usually at 90° from the direction of the air outlet.

This type of fan is suited to applications that require a high airflow rate but at low system restriction pressures. Due to the reduced overall height of this product type it is particularly suited to high flow rate applications within a reduced space envelope. This type of product has similar characteristics to a regular forward curved fan in terms of its power usage, but has a lower overall efficiency than a regular forward curved fan.

Due to the blade length and proximity to the scroll housing’s inlet, these types of fans are can suffer from excessive noise levels or blade passing noise. These fans are also not suited to higher pressure applications and quickly become unstable when subjected to higher system restriction pressures.

Radial bladed fans

Radial bladed fans are in some ways similar to a backward curved impeller, but have straight impellers blades typically angled backwards from the direction of rotation but can sometimes be vertical from the impeller axis.

Radial bladed fans act in a very similar way to a regular backward curved fan but for most applications require the use of a fan scroll to provide directionality of flow and convert some air velocity into static pressure. Radially bladed impellers can used for recirculation fans to spread air in all directions, such as in an oven. For recirculation type fans, the impeller is usually of a single piece construction (without an inlet shroud) and has fewer blades and a more open construction. This is to prevent the build-up of contamination on the impeller blades (e.g. soot), particularly in high temperature applications where exhaust gasses are being handled.

Radially bladed fans can also be used in applications that require the fan to have reversible direction of operation in which case the quantity of blades can be higher and are orientated radially from the rotational axis. Depending on the design of impeller used, the power requirement can vary significantly as can overall efficiency, but in general these types of impellers are less efficient than a backward curved fan.